Helipad Relocation

Partners HealthCare, Brigham and Women’s Hospital

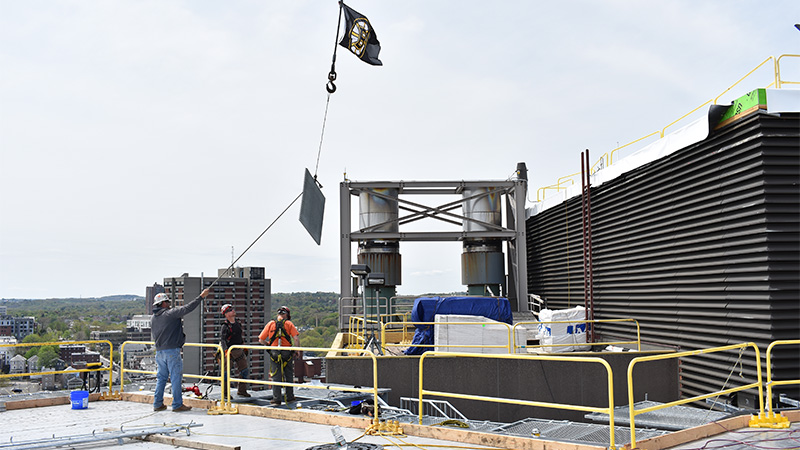

Working at New Heights.

Driven by the challenge to overcome a myriad of dangerous obstacles, the Walsh Brothers team brainstormed a plan that successfully fast-tracked a project that also met the owner’s schedule, cost and safety goals.

The task was to relocate a helipad at Brigham and Women’s Hospital atop a 16-story inpatient hospital tower which involved extending two existing elevator shafts to reach the new helipad location for emergency access. Some say this project may not have ever happened if not for the ingenuity of the Walsh Brothers team and their ability to defend the plan to local authorities and regulators.

The list of challenges to overcome on a project site located 265 feet in the open air, are many. Laydown area, working space, safety railings, fall protection, access to the job site, and determining how materials are arriving are only a few. Imagine the safety concerns for the general public, patients and employees while building over one of the hospital’s main entrance and surrounding sidewalks. Additionally, the street directly below the project (Shattuck Street) is the main road traveled for ambulance access to both Brigham and Women’s as well as Boston Children’s Hospital. The challenge of how NOT to interfere with the work of the medical staff and patient care and residents of the neighborhood was the main priority in the planning.

During preconstruction and planning (or Design Progress Management), Walsh Brothers led the design team in feasibility and constructability analysis. Our team brought in code, structural and safety specialist to assist in analyzing various options for constructing this project from both inside and outside the hospital. How could we keep all four existing elevators active while extending two? Should street shut-downs for weekend crane work be used or was there another way to keep the job running and impact the neighborhood less?

Walsh Brothers’ bold and unusual ideas and careful coordination of the work ensured minimal disruption to ongoing hospital operations. To do so, our team proposed a tower crane to be installed atop the adjacent building roof supported by the existing concrete structure in part, but also installing two structural steel “stilts” extending to the street to sit atop basement columns below and support the dunnage frame for the crane. The use of a tower crane would significantly reduce the impact of road closures for both ambulances, local residences and maintain all important Fire Department access to each building along Shattuck Street. This addressed the safety issue and as minimized street shutdowns and premium time staff costs from 20 weekends to two and allow for continuous live loading from the street below during weekdays. As added safety measures full height building staging and scaffold systems were designed to create a working platform and safety zone for this unique project site.

The much-needed elevators were designed to be prefabricated and built on the outside of the tower, to not interfere with the already over-burdened elevators used by patients and staff. Critical MEP/FP components servicing the new helipad were also designed and coordinated as prefabricated units to further assist in a seamless and quality installation.